About Us

TNC WIRECUT BRICKS was established in the year 2008 with the sole purpose of serving the construction industry. Mr.Thirugnanam, the managing Director of TNC WIRECUT BRICKS, is an enthusiastic business person with futuristic vision and hard found experiences.

It is his determination and good will that has got the company all its glory and great heights. Under his guidance and approach the company has flourished and with more than 3 decades of solid experience in brick manufacturing.

We are now a pioneer in Quality clay brick manufacturing and we employee up-to-date technology to offer our customers a high quality Brick.

|

1. INTRODUCTION:

The fundamentals of brick manufacturing have not changed over time. However,

technological advancements have made contemporary brick plants substantially

more efficient and have improved the overall quality of the products. A more

complete knowledge of raw materials and their properties, better control of firing,

improved kiln designs and more advanced mechanization have all contributed to

advancing the brick industry. Other Technical Notes in this series address the

classification and selection of brick considering the use, exposure and required

durability of the finished brickwork.

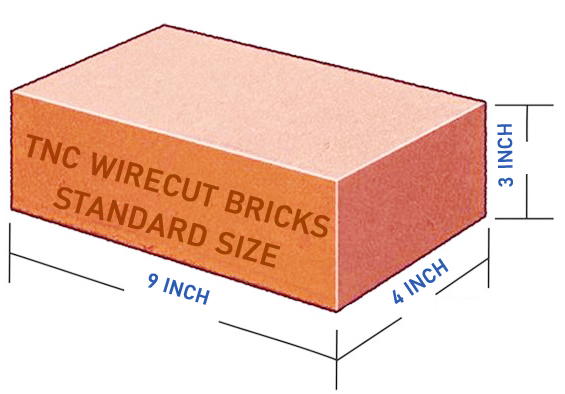

2. PRODUCT & ITS APPLICATION:

Brick is made of clay or shale formed, dried and fired into a durable ceramic

product. There are three ways to form the shape and size of a brick: extruded

(stiff mud), molded (soft mud) and dry-pressed. The majority of brick are made by

the extrusion method. Brick achieves its color through the minerals in the fired

clay or through coatings that are applied before or after the firing process. This

provides a durable color that never fades or diminishes. Brick shrink during the

manufacturing process as vitrification occurs. Brick will vary in size due to the

manufacturing process. These variations are addressed by ASTM standards. The

method used to form a brick has a major impact on its texture. Sand-finished

surfaces are typical with molded brick. A variety of textures can be achieved with

extruded brick. Brick manufacturers address sustainability by locating

manufacturing facilities near clay sources to reduce transportation, by recycling

of process waste, by reclaiming land where mining has occurred, and by taking

measures to reduce plant emissions. Most brick are used within 500 miles of a

brick manufacturing facility.

3. DESIRED QUALIFICATIONS FOR PROMOTER:

Graduate in any graduate.

4. INDUSTRY LOOK OUT AND TRENDS

The global concrete block and brick manufacturing market is gaining from the

booming construction sector worldwide. Rapid urbanization leading to the

demand for new housing units in developing countries is stoking demand for

concrete blocks and bricks. For instance, Brazil is a key domestic market in Latin

America in terms of manufacturing volume of concrete blocks and bricks.

Concrete blocks are preferred in the construction of walls as they are less

susceptible to damage and provide insulation as well.

Apart from this, foreign direct investments in manufacturing and construction

sectors in several countries of Asia Pacific have led to significant expansion of the

concrete block and brick manufacturing market in recent years.

The emergence of eco-friendly building materials has been significant factor

acting in favour of this market predominantly in developed regions. Countries in

North America and Europe are increasingly shifting towards sustainable

construction with the introduction of green building materials. Eco-friendly

building materials such as autoclaved aerated concrete (AAC) are obtained from

non-toxic ingredients and industrial waste that do not leave fumes, unlike

synthetic building materials.

5. MARKET POTENTIAL AND MARKETING ISSUES, IF ANY:

The construction sector is an important part of the Indian economy with the

contribution of 10% in the GDP and is registering an annual growth of 9%. Clay

fired bricks are the backbone of this sector. The Indian brick industry is the

second largest producer of bricks in the world after China. India is estimated to

produce more than 14000 crores of bricks annually, mainly by adopting age -old

manual traditional processes. The brick sector consumes more than 24 million

tons of coals annual along with huge quantity of biomass fuels. The per annum

O2 emissions from Indian brick industry are estimated to be 42 million tons. Due

to large scale construction activities in major towns and cities, a number of brick

plants have been set up on the outskirts of these cities. The Asia’s overall

production has increased from almost 77 percentages to 86.67 percentage of

total production of world.

INDIAN SCENARIO

Indian Brick Kiln industry is the second largest producer in the world after china,

as per the 2015, estimates production has been increasing annually from 5-10

percentages due to rapid expansion of the urbanization and real estate sector.

India estimated to have more than 150000 registered and unregistered brick

kilns; producing more than 250 billion bricks. The main cost components of these

industries are labour, coal, land, mud, rent and electricity; since it is the largest

consumer of coal after the power and thermal sector, it is consuming around 25

million tons every year. Indian brick kilns expanded their capacity of production

from 150 billion in 2015 to 200 billion in 2020, almost 150 percentages in the

total world production. It consumes 350 billion tons of clay; employing 10 million

people, which is twice to the China’s brick kiln but ten times lower than the

China’s employee production capacity.

6. RAW MATERIAL REQUIREMENTS:

Clay is one of the most abundant natural mineral materials on earth. For brick

manufacturing, clay must possess some specific properties and characteristics.

Such clays must have plasticity, which permits them to be shaped or molded

when mixed with water; they must have sufficient wet and air-dried strength to

maintain their shape after forming. Also, when subjected to appropriate

temperatures, the clay particles must fuse together. Types of Clay Clays occur in

three principal forms, all of which have similar chemical compositions but

different physical characteristics. Surface Clays. Surface clays may be the up

thrusts of older deposits or of more recent sedimentary formations. As the name

implies, they are found near the surface of the earth. Shales Clay: shale’s clay is

clays that have been subjected to high pressures until they have nearly hardened

into slate. Fire Clays: Fire clays are usually mined at deeper levels than other

clays and have refractory qualities. Surface and fire clays have a different

physical structure from shale’s but are similar in chemical composition. All three

types of clay are composed of silica and alumina with varying amounts of

metallic oxides. Metallic oxides act as fluxes promoting fusion of the particles at

lower temperatures. Metallic oxides (particularly those of iron, magnesium and

calcium) influence the color of the fired brick. The manufacturer minimizes

variations in chemical composition and physical properties by mixing clays from

different sources and different locations in the pit. Chemical composition varies

within the pit, and the differences are compensated for by varying manufacturing

processes. As a result, brick from the same manufacturer will have slightly

different properties in subsequent production runs. Further, brick from different

manufacturers that have the same appearance may differ in other properties.

7. MANUFACTURING PROCESS:

There are four different operations are involved in the process of manufacturing

of bricks:

1. Preparation of clay

2. Molding

3. Drying

4. Burning

1. Preparation of clay for brick manufacturing:

Preparation of clay for bricks manufacturing is done in six steps: Unsoiling of clay

we need pure clay for the preparation of bricks. The top layer of soil may contains

impurities, so the clay in top layer of soil about 200mm depth is thrown away.

This is called unsoiling. Digging After the removal of top layer, the clay is dug out

from the ground and spread on the plain ground. Cleaning In this stage, the clay

is cleaned of stones, vegetable matter etc. if large quantity of particulate matter

is present, and then the clay is washed and screened. The lumps of clay are

converted into powder with earth crushing rollers. Weathering the cleaned clay is

exposed to atmosphere for softening. The period of weathering may be 3 to 4

weeks or a full rainy season. Generally, the clay is dug out just before the rainy

season for larger projects. Blending if we want to add any ingredient to the clay,

it is to be added in this stage by making the clay loose and spread the ingredient

over it. Then take small portion of clay into the hands and tuning it up and down

in vertical direction. This process is called blending of clay. Tempering In this

stage, water is added to clay and pressed or mixed. The pressing will be done by

cattle or with feet of men for small scale projects, pug mill is used as grinder for

large scale projects. So, the clay obtains the plastic nature and now it is suitable

for molding.

2. Molding of clay for brick manufacturing

In the molding process, prepared clay is mold into brick shape (generally

rectangular). This process can be done in two ways according to scale of project.

Hand molding (for small scale)

Machine molding (for large scale)

Hand molding of bricks

If manufacturing of bricks is on a small scale and manpower is also cheap then

we can go for hand molding. The molds are in rectangular shape made of wood or

steel which are opened at the top and bottom. The longer sides of molds are

projected out of the box to serve it as handles. If we take durability in

consideration steel molds are better than wooden molds. In hand molding again

there are two types and they are Ground molded bricks, Table-molded bricks

Machine molding of bricks

The bricks required are in large quantity, and then machine molding is

economical and also saves more time. Here also we are having two types of

machines, Plastic clay machines, and Dry clay machines

Plastic clay machines: These machines contain an opening in rectangular shape

and when we place the tempered clay in to this machine it will come out through

this opening. Now, the rectangular strips coming out the opening are cut by wires

to get required thickness of brick. So, these are also called wire cut bricks. Now

these raw bricks are ready for the drying process. Dry clay machines: Dry clay

machines are more time saving machines. We can put the blended clay into

these machines directly without tempering. Means tempering is also done in this

machine by adding some water. When the required stiffness is obtained the clay

is placed in mold and pressed hard and well-shaped bricks are delivered. These

are called pressed bricks and these do not require drying they may directly sent

to burning process.

3. Drying of raw bricks

After molding process the bricks contain some amount of moisture in it. So,

drying is to be done otherwise they may cracked while burning. The drying of raw

bricks is done by natural process. The bricks are laid in stacks. A stack consists 8

to 10 stairs. The bricks in these stacks should be arranged in such a way that

circulation of air in between the bricks is free. The period of drying may be 3 to

10 days. It also depends upon the weather conditions. The drying yards are also

prepared on higher level than the normal ground for the prevention of bricks from

rain water. In Some situations artificial drying is adopted under special dryers or

hot gases.

4. Burning of bricks

In the process of burning, the dried bricks are burned either in clamps (small

scale) or kilns (large scale) up to certain degree temperature. In this stage, the

bricks will gain hardness and strength so it is important stage in manufacturing of

bricks. The temperature required for burning is about 1100oC. If they burnt

beyond this limit they will be brittle and easy to break. If they burnt under this

limit, they will not gain full strength and there is a chance to absorb moisture

from the atmosphere. Hence burning should be done properly to meet the

requirements of good brick.